Even though retailers carry hundreds, even thousands, of different styles of rings, some customers still have difficulty finding one with all the qualities they’re looking for. Customers saying, “If I could just have Ring A with this part from Ring B, it would be perfect,” is an everyday occurrence. Fortunately, today’s shoppers no longer have to settle! Jewelry lovers now have the option to create personalized rings, thanks to the transformative technology of 3D printing.

What is 3D Printing?

In case you’ve been technologically out of touch for a year or two, 3D printers are advanced tools capable of printing three-dimensional objects.

Whereas a standard printer creates text or an image with a single layer of ink on a sheet of paper, a 3D printer receives a set of digital files that includes instructions for multiple layers that will be “printed” one on top of the other to create a specific object. The printer begins with the bottom layer of the object and then continues to print the thinly-sliced layers on top of one another until the object is complete.

3D Printing in the Jewelry Industry

3D printing is now used to create many different types of products, including electronics, prosthetics, dental models, and even airplane parts. But one of its most exciting uses is found in the jewelry industry, where 3D printing has given consumers the power to design and create exquisite custom pieces.

Before 3D printing, jewelers had to spend hours carving out a detailed wax model from a larger wax block by hand. This model would then be used to create a piece of jewelry. However, due to the time and energy it took to design just one piece, it was very difficult for jewelers to offer custom pieces to their customers, which is why custom jewelry is often associated with high-end stores and exorbitant prices.

3D printing speeds up the process exponentially by producing the wax model in a fraction of the time that it takes to carve it by hand. Not only does it save jewelers time and effort, it also gives them more creative freedom, since 3D printed waxes aren’t limited like hand-carved waxes. With 3D printing, jewelers can now allow customers to create custom pieces at much more affordable prices.

How to Create Personalized Rings Using 3D Printing

The first step to creating a custom ring using 3D printing is designing it. Jewelers will work with interested parties to get detailed information on what kind of ring they’re looking for. Some customers will have a strong idea of what they want and will come prepared with pictures or Pinterest boards full of ideas. Some may need a little more guidance (check out some of our design tips here and here).

Once a design has been decided upon, a jeweler will use CAD (computer aided design) software to put together the design and print a mold of the finalized design. Using this software is not easy—in fact, jewelers and designers must receive up to two years of training before they are able to use CAD to create custom pieces! This is the same software that is used by engineers and architects, but creating a piece of jewelry is often more difficult than creating prosthetics or building materials because of the level of detail that is involved for the extremely small scale of the jewelry world.

Using CAD, jewelers can create a three-dimensional drawing of a ring and can view the drawing at different angles to make sure it is perfect.

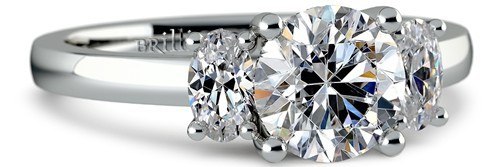

If the images are approved, the designer will move forward and begin the process of lost-wax casting, which involves making a wax model of the approved design. The model will be compared to the three-dimensional drawings to ensure that the designs match and will then be sent to a casting facility.

At this point, the wax model is put inside a container and covered with liquid plaster to create the mold. The plaster is then left to set. Once solid, it is heated slowly to ensure that no moisture remains and to prevent the mold from going into heat shock when placed in an ultra-hot kiln.

The mold is placed in the kiln to melt and shed the original wax model, leaving behind an impression of the ring. The mold is cooled, then filled with liquid precious metals such as silver, gold, or platinum to create the ring band and setting. The final step is removing the plaster to reveal the fabulous finished product.

Lost-wax casting an intensive process that can take up to a week and requires great skill and resources.

The Benefits of Using 3D Printing

3D printing makes it possible for more people to create custom-designed rings because it simplifies the process and makes it easier for jewelers to offer this service to customers. It also gives customers the opportunity to create intricately-designed rings that no one else will have and would not have been possible even just a few years ago. It’s easy to add details such as scrollwork, filigree, vines, and unique stones to a ring, so you have the creative freedom to incorporate any of these elements into your design.

3D printing also makes it easier for customers to recreate a design they saw on their favorite celebrity. Instead of searching high and low to try to find out where you can find an inexpensive version of the ring your favorite celebrity is wearing, you now have the power to create your own using 3D printing!

Custom image

3D printing is also much more sustainable than other manufacturing processes. It is referred to as “additive manufacturing” because it continues to add materials, layer upon layer, until the final product is complete, thus producing no waste. This differs from other manufacturing processes, which typically begin with a large block of material and cut away or carve out pieces until the final product has been created.

To learn more about how you can create personalized rings using 3D printing, contact a Brilliance representative today. We would be happy to walk you through the process of creating a custom ring using advanced 3D printing technology!